This post may contain affiliate links which may generate a small commission from clicks that result in a purchase.

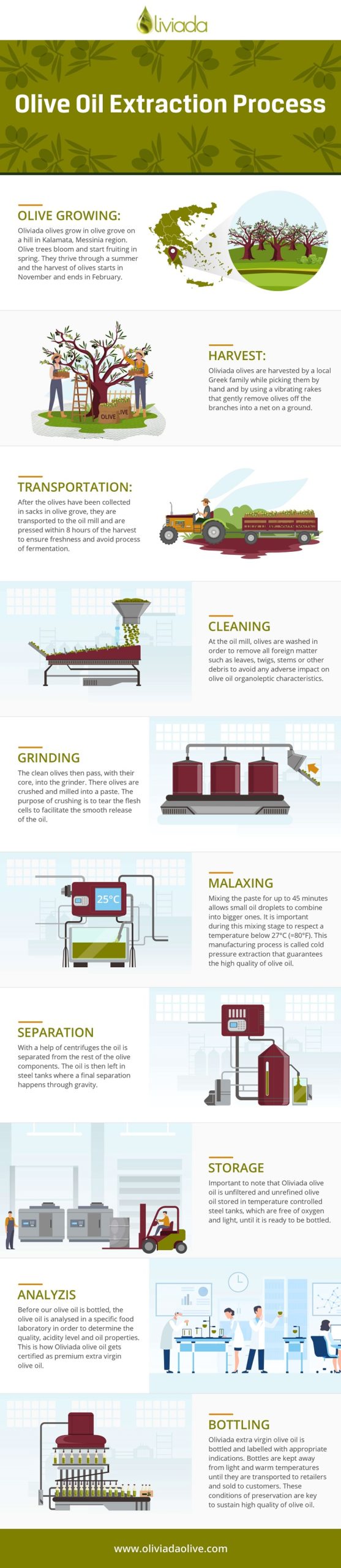

In this article, I share with you our Oliviada extra virgin olive oil extraction process step by step with our video, pictures and infographic.

Let’s start by watching video made in 2021 with detailed processing stages defined down below!

We use modern olive oil processing which consists of 3 main processes: crushing, malaxing, and centrifugation. This method as well known as the first cold-pressed olive oil extraction process which avoids overheating uses mechanical means only, with no chemical treatment involved.

1. OLIVE GROWING

Oliviada olives grow in an olive grove on a hill in Kalamata, Messinia region. Olive trees bloom and start fruiting in spring. They thrive through summer and the harvest of olives starts in November and ends in February.

2. HARVEST TIME

Oliviada olives are harvested by a local Greek family while picking them by hand and by using vibrating rakes that gently remove olives off the branches into nests that have been placed under the tree canopy.

3. TRANSPORTATION

After the olives have been collected in sacks in olive grove, they are transported to the oil mill and are pressed within 8 hours of the harvest to ensure freshness and avoid process of fermentation.

4. CLEANING STAGE

At the oil mill, olives are washed in order to remove all foreign matter such as leaves, twigs, stems or other debris to avoid any adverse impact on olive oil organoleptic characteristics.

5. GRINDING STAGE

The clean olives then pass, with their core, into the grinder. There olives are crushed and milled into a paste. The purpose of crushing is to tear the flesh cells to facilitate the smooth release of the oil from the vacuoles.

6. MALAXING THE PASTE

Malaxing or mixing the paste for up to 45 minutes allows small oil droplets to combine into bigger ones. It is important during this mixing stage to respect a temperature below 27°C (80°F). This manufacturing process is called cold pressure extraction that guarantees the high quality of olive oil.

7. SEPARATION STAGE

With a help of centrifuges the oil is separated from the rest of the olive components. The oil is then left in steel tanks where a final separation happens through gravity.

8. STORAGE

Important to note that Oliviada olive oil is unfiltered and unrefined olive oil stored in temperature controlled steel tanks, which are free of oxygen and light, until it is ready to be bottled.

9. ANALYZIS

Before our olive oil is bottled, the olive oil is analysed in a specific food laboratory in order to determine the quality, acidity level and oil properties. This is how Oliviada olive oil gets certified as premium extra virgin olive oil.

If you are interested to learn a difference in olive oils, check out our article: extra virgin olive oil vs regular olive oil.

10. BOTTLING

Oliviada extra virgin olive oil is bottled and labeled with appropriate indications. Bottles are kept away from light and warm temperatures until they are transported to retailers and sold to customers. These conditions of preservation are key to sustain a high quality of olive oil.

Generic FAQs

How long does it take to make olive oil?

After olives are harvested and brought to a mill for further olive processing, it takes up to 2 – 3 hours to extract an olive oil (depending on the volume of olives). Overall, it takes fewer than 8 hours from olive harvest to high-quality olive oil production.

When is the best time to harvest olives?

The best time to harvest depends on what quality olive oil you want to get. For the Mediterranean zones:

* At the beginning of November, early harvest unripe olives have a low yield but have a peppery and bitter flavor, high sensory qualities, and extremely low acidity.

* In December- January, olives are ripened well which increases yield in terms of release of olives from the tree branches.

* However, over-mature olives at the end of January do not possess the best sensory qualities for oil production.

Therefore, the best olive harvesting time is frequently a compromise between harvesting efficiency and final oil quality.

What is cold extracted olive oil?

Cold extraction ensures the highest quality for extra virgin olive oil. Cold extraction refers to a temperature lower than 80.6F (27C) during crushing the olive paste. This way of extracting olive oil ensures the highest level of polyphenols, nutrients, aromas, and flavors are preserved.

As well, sometimes you hear the first cold-pressed olive oil, where first refers to the olive oil production from the first crushing of olives. As a result, it ensures a superior taste and greater health benefits.

How do you extract extra virgin olive oil?

As to get the top-grade extra virgin olive oil, the olives must be pressed just once within 8 hours after harvest and olive oil extracted by using mechanical means at a mill. By using the first cold extraction method where no heat or chemicals involved comparing to refined oil.

As a result of cold extraction, you make the best taste and aroma of olive oil, containing a high level of nutrients and antioxidants with extremely low acidity.

Conclusion on Oliviada Olive Oil Extraction Process

Overall, Oliviada olive oil is unfiltered and processed by using the first cold pressure methodology. That way it keeps a high level of polyphenols, antioxidants, and vitamins and has extremely low acidity.

Also, while Oliviada extra virgin olive oil aligns closely with organic practices by prioritizing natural, eco-friendly farming and production techniques, it stands distinct from certified organic olive oil due to the absence of formal organic certification, offering a high-quality, conscientiously made product that prioritizes tradition, quality, and sustainability.

Hopefully, this article gives you an insightful overview of the olive oil extraction process. If you are interested in a taste of the Mediterranean heaven, get our premium quality extra virgin olive oil at Oliviada shop here.

Read Next

Also Relevant

- Olive Oil Press Machine for Home Use

- Extra Virgin Olive Oil vs Olive Oil

- Best Olive Oil Worldwide

- 40+ Practical Olive Oil Uses

Join our Facebook community: Olive Tree Growers and Enthusiasts

Hi, I’m Vangelis Kleftogiannis, the founder of Oliviada and an established olive oil expert from Kalamata, Greece. My expertise isn’t just in producing quality Extra Virgin Olive Oil, but also in the cultivation and care of olive trees themselves. I am deeply committed to sharing my knowledge and know-how, helping others understand the intricacies of olive tree growing and the creation of quality olive oil.